We also offer our regular and prospective customers the manufacture of one-layer PCBs without vias and two-layer PCBs with vias.

Production Capabilities

- Printed circuit boards:

- 2 layer, 1 layer

- Material used:

- FR4, Tg=135 °C (others on demand)

- Material thickness:

- 1.5 mm – standard (others on demand)

- Cu thickness:

- 18 µm, 35 µm – standard (others on demand)

- Max. PCB size:

- 560 x 300mm

- Smallest hole:

- 0,25mm

- Min. trace clearance:

- 200um

- Surface finish:

- HAL

- Solder stop mask:

- Green colour – standard (others on demand)

- Service marking:

- White colour – standard (others on demand)

- Processing:

- Cutting, milling, V-grooving

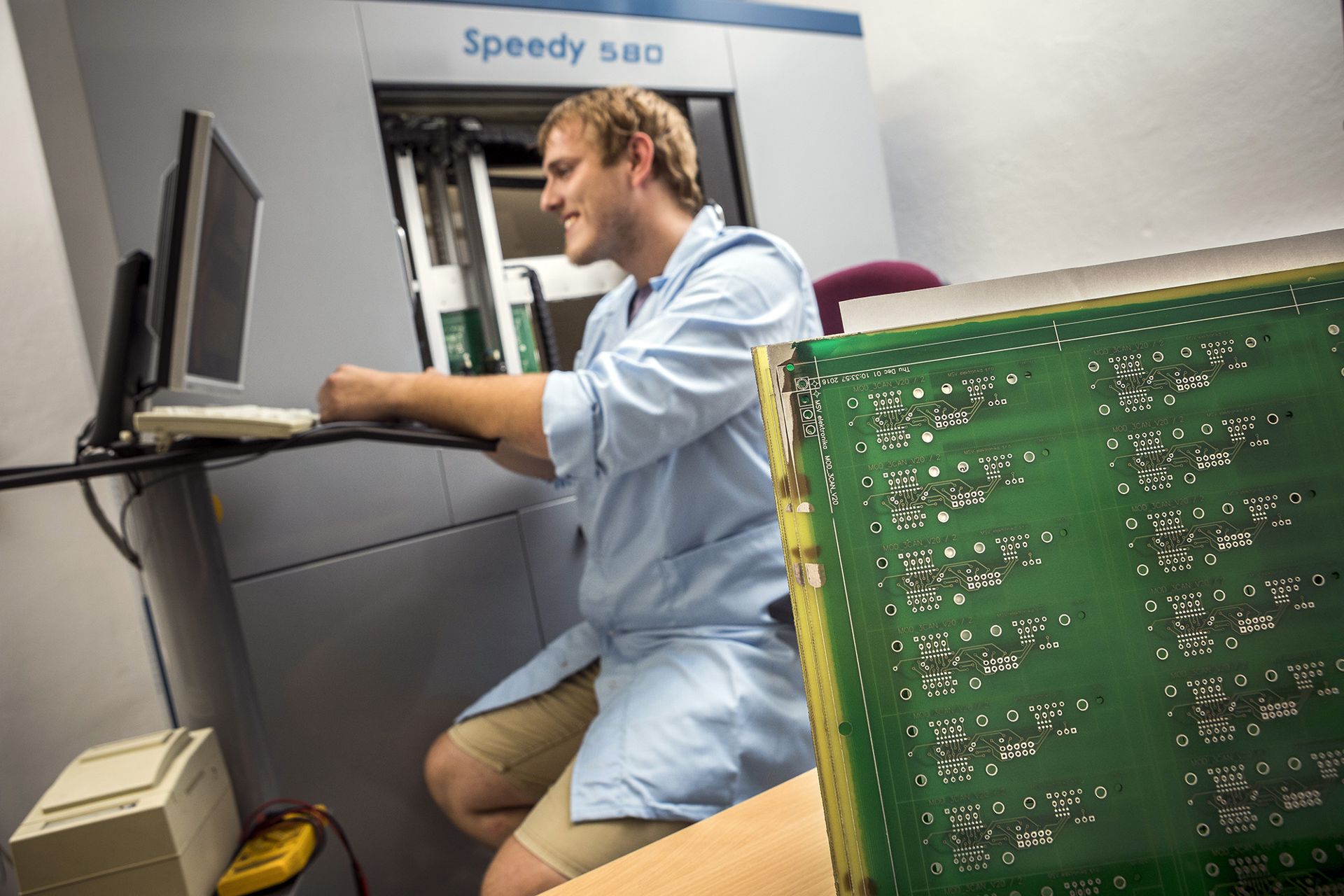

- El. testing:

- Speedy 580

- Data processing (formats):

- Gerber RS 274X, Gerber – 274D, or EMMA

- Data processing (drilling):

- Excellon or Merona

- Delivery time:

- as agreed

Technologies Used for PCB Production

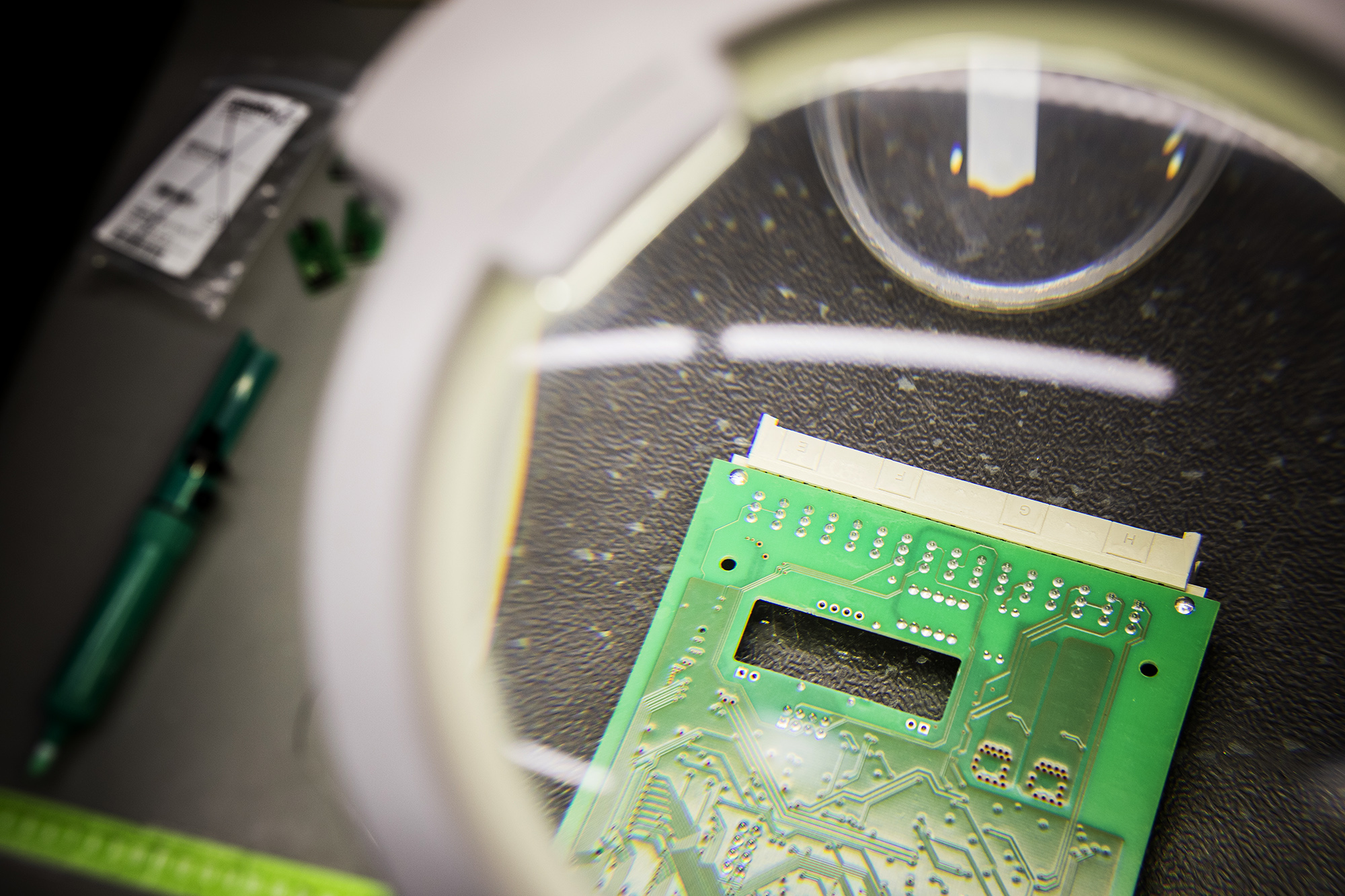

Drilling and Milling

LENZ GX-550-1 – CNC drilling/milling machine fitted with PRECISE spindle with air bearings with speed of 20-120,000 rpm. The device is used for drilling and milling printed circuit boards with hole sizes from 0.5 mm to 6.5 mm.

Grooving

JUSTUR-DRAK – CNC grooving machine for creating V-grooves (V-scores), required for the final splitting of PCB production blanks. Grooves are created on both sides of the board using two diamond circular saws.

Galvanising Line

DPSVL26 – Vertical galvanising line for metal-plating holes in printed circuit boards. Includes 2 galvanising and 1 tin-plating bath fitted with Cu and Sn anodes. The line is fully automated and controlled by a production programme.

Photoplotter

MIVA 1620 – The device is used for creating photo plots for subsequent exposure on photosensitive materials.

Etching and Developing Line

HL09 etching line and HL07 developing line – Horizontal line for etching Cu layers using cuprous chloride. The line is fitted with a 740 mm long etching module, 3-cascade rinsing module and a drying module. It also features an rh probe for automatic refilling of the etching solution. Horizontal line for developing dry resist and solder stop masks. The development chamber is 598 mm long. Fitted with a 3-cascade rinsing + drying module.

Hot Air Levelling

HAL Penta 450 – Device for tin-plating finished PCBs with lead-free tin. Max. blank size of 400x450 mm. Features 2 immersion and vibration options.

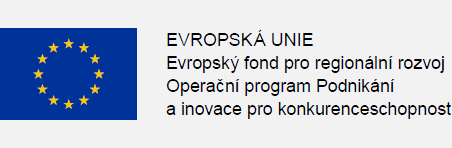

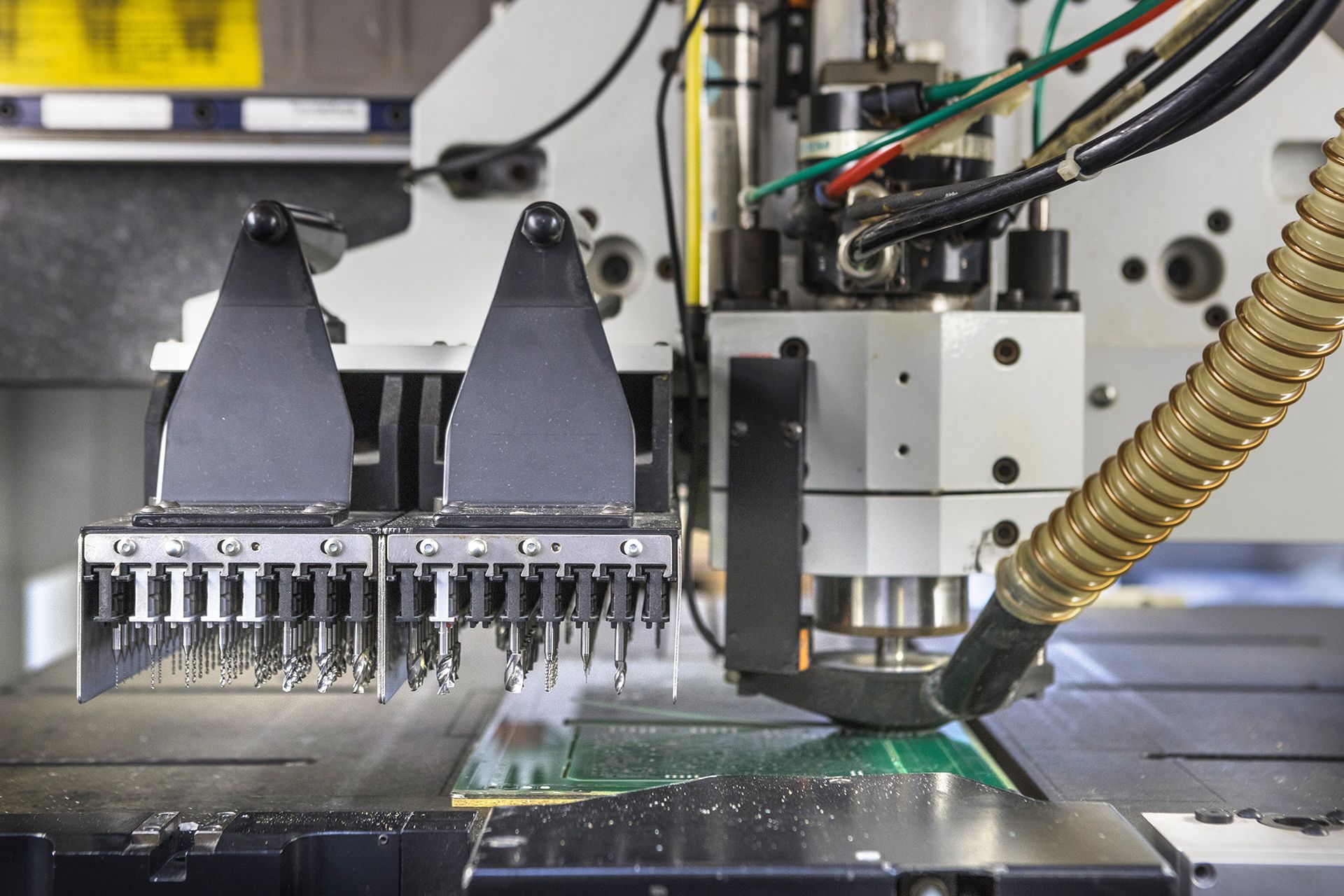

Electrical PCB Testing

SPEEDY 580 PCB tester – Device used for final testing of produced PCBs. Using a pre-created testing programme, the machine can detect discontinuous circuit paths/holes and random short circuits. The machine is fitted with 4 testing heads.